Made In Italy

The Carbon vehicle combines design skills and production techniques belonging to various Italian industrial and artisan sectors, guaranteeing a very high quality level.

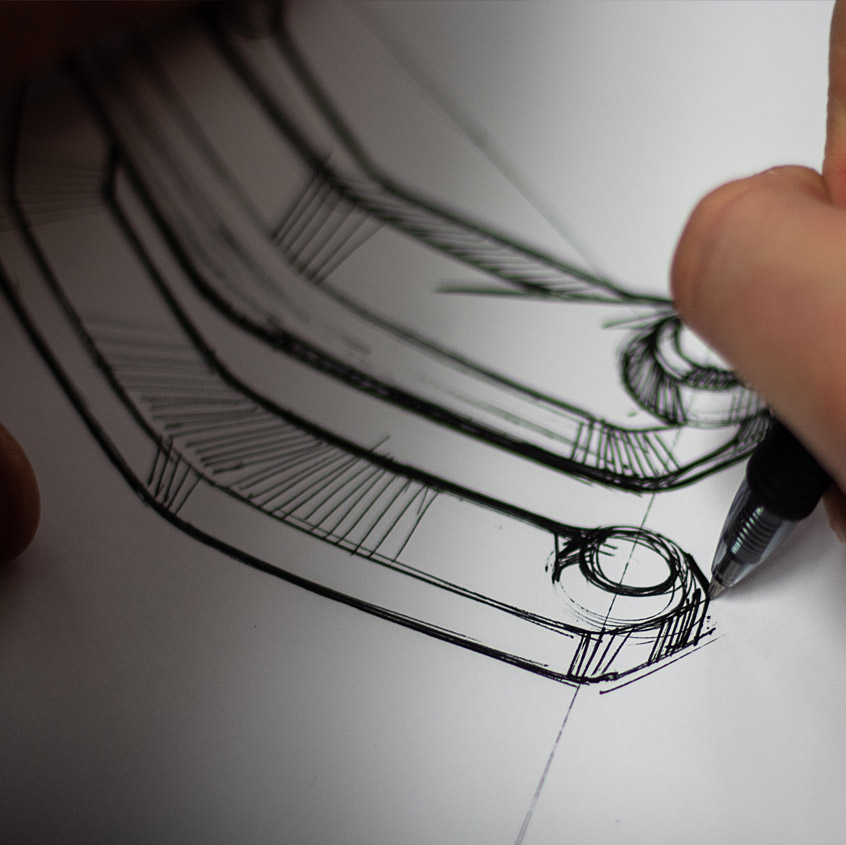

The frame and fork arms are made of carbon by a leading company in the automotive sector based in Emilia Romagna, home of the famous Motor Valley. By combining technical skills and aesthetic needs, it was necessary to define two different production processes for the components produced in carbon fiber, thus ensuring the desired structural behavior without detracting from the visual impact.

All the parts in composite material are manually laminated by specialized operators and after various autoclave firings are extracted from the molds. Frame and fork are proudly maintained in carbon look to enhance their beauty and details, such as the herringbone crossing under the seat.

The central frame, the swingarm and the levers that make up the suspension systems are produced in aluminum to ensure structural strength, lightness and excellent surface finish.

The swingarm in particular is made from aluminum sheets that are modeled, worked and welded manually by craftsmen specialized in the production of unique pieces for the motorsport sector.

The central frame and all the other aluminum components, on the other hand, are produced by means of computerized machining centers with chip removal that allow to perform very complex processes aimed at obtaining light components, with unique shapes and with excellent mechanical characteristics.

After the production of the raw components there is the painting phase.

This phase allows to obtain a one-of-a-kind vehicle that fully satisfies the customer’s requests. The Moto Parilla team offers a very high level customization service thanks to the collaboration of the company designers with the painters used by the company.

The carbon fiber and aluminum components are subjected to various preparation steps prior to painting. The central frame and the swingarm are initially subjected to powder coating that allows to create a durable and resistant base, the various levers are subjected to aesthetic anodic oxidation in different colors while the fiber parts are manually sanded and prepared.

At the end of the preliminary painting phase, liquid painting is carried out in the various colors according to the requests.

The painting process has been studied in detail to enhance the beauty of the various components and their respective materials while ensuring durability and finish.